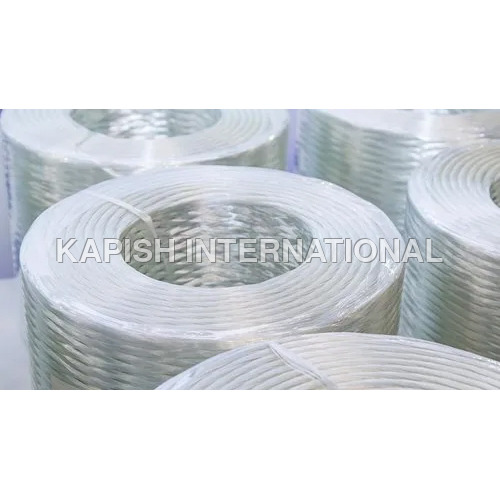

Fiberglass Pultrusion Roving

70 INR/Kilograms

Product Details:

- Color Silver

- Usage Industrial

- Product Type Fiberglass Pultrusion Roving

- Size Different Available

- Material Fiberglass

- Click to View more

X

Fiberglass Pultrusion Roving Price And Quantity

- 70 INR/Kilograms

- 10000 Kilograms

Fiberglass Pultrusion Roving Product Specifications

- Silver

- Fiberglass Pultrusion Roving

- Industrial

- Different Available

- Fiberglass

Fiberglass Pultrusion Roving Trade Information

- 100000 Kilograms Per Month

- 7 Days

- All India

Product Description

Fiberglass Pultrusion Roving is a kind of fiberglass reinforcement material utilized in pultrusion processes to produce composite products. Pultrusion is a constant process where fiberglass roving is pulled through a resin bath and thereafter shaped by a heated die to form a lightweight, rigid profile. This type of roving is made by assembling constant glass fibers together with a sizing agent, promoting adhesion to the resin. It is designed to have continuous tension and tremendous wet-out properties to guarantee consistency in the final product. Fiberglass Pultrusion Roving is usually utilized in applications like bridge decks, window frames, and ladder rails, where high durability and strength are required.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email